Phone

+86 133 9069 2151

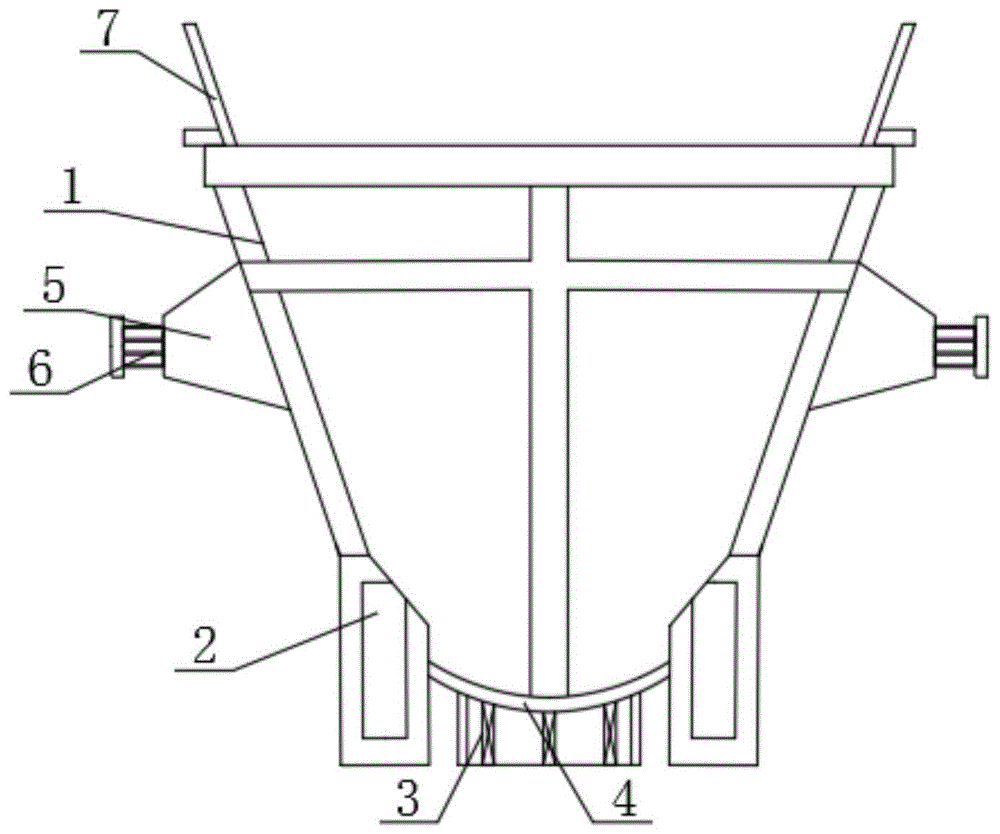

Descripion:Ductile iron slag pot is a container made of ductile iron material, which is mainly used to carry molten metal slag during the casting process.

Ductile iron slag pot is a container made of ductile iron material, which is mainly used to carry molten metal slag during the casting process. Ductile iron is a cast iron material with high strength, high toughness, high wear resistance and excellent corrosion resistance. During the casting process, by adding a certain amount of nodularizing agent and inoculant, the graphite form in the cast iron is changed from flake to spherical, thereby improving the mechanical properties and processing performance of the cast iron. Ductile iron slag pots are made on the basis of this material and have high use value and wide range of applications.

Application of Ductile Iron Slag Pot in Foundry Industry

● During the casting process, the molten metal will produce a large amount of dross, which needs to be cleaned up in time to ensure product quality. The ductile iron slag pot is a container used to carry these molten metal slags. It can withstand high temperatures and corrosion to ensure the smooth progress of the casting process.

● It can effectively improve the production efficiency of the foundry industry. Because it has excellent high temperature resistance and corrosion resistance, it can be used for a long time without frequent replacement, thus reducing downtime and maintenance costs in production.

● It can effectively guarantee the quality of casting products. It can effectively isolate molten metal and dross, prevent dross from being mixed into the product, thereby improving the purity and quality stability of the product.

Manufacturing process

● Material selection: The main material of the ductile iron slag pot is ductile iron, which requires the selection of high-quality cast iron raw materials and strict inspection and screening.

● Smelting and spheroidizing treatment: Smelt the selected cast iron raw materials, and add an appropriate amount of spheroidizing agent and inoculant to transform the graphite in the cast iron into a spherical shape.

● Casting and processing: The smelted ductile iron is cast, usually by sand casting or metal mold casting. After the casting is completed, processes such as mechanical processing and heat treatment are required to ensure the dimensional accuracy and mechanical properties of the slag pot.

● Inspection and quality control: During the manufacturing process, strict inspection and quality control are required for each link to ensure that the quality and performance of the slag pot meet standard requirements.

Product features

● It has high strength and toughness, can withstand high temperatures and heavy pressure, and ensures the smooth progress of the casting process.

● Able to resist corrosion from molten metal and slag, extend service life and reduce maintenance costs.

● The surface has been specially treated and has good wear resistance, which can reduce the wear of metal slag on the tank body.

● The structure is strong and stable, able to withstand the weight and pressure of molten metal slag, keeping the shape and function of the tank intact.

● After strict quality inspection and testing, it is safe and reliable, ensuring the safe storage and transportation of metal slag.

+86 133 9069 2151

sale@kfqizhongji.com

Copyright © KUNFENG Slag Pot | Powered by KUNFENG Heavy Industry (Suzhou) Co., Ltd.

What'sApp:+86 15366477186