Slag pot is important device in steel making. It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes. It is bowl-shaped container with lifting lugs at both sides. A grilling is installed inside the pot, under at least 300 mm of the upper surface and divides the inner pot into some pieces. The slag pot that purchased by metallurgical enterprises generally is made by traditional cast process with long manufacturing cycle, short service life, and great scrapped quantity. KUNFENG Slag Pot has more advantage such as cast period short, long service life and strong resistance to deformation.

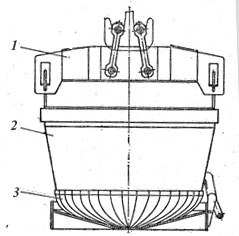

Main components of the Slag bucket:

1.travers

2.tub

3.bottom

The tub consists of the welded shell ring and bottom made from flexible plate sectors. Sectors are pivotally connected to the shell ring at the wide end. The narrow end of the sector has the eyelet. Locking chains are threaded through all of the eyelets to lock the bottom. One end of chains is permanently attached to the sector, the others are closed to the lock with the bolt connected to the lever.

No. | Parameter name | 1.5t | 3t | 6t | 12t |

1 | Charging bucket volume, m³ | 1.3 | 2.6 | 5.4 | 12.0 |

2 | Bulk density of the charge mix, kg/m³, not less than | 1150 | 1150 | 1120 | 1000 |

3 | Load capacity, kg, not more than | 1500 | 3000 | 6000 | 12000 |

4 | Charging bucket weight, kg | 1480 | 1790 | 3150 | 7000 |

Features:

1. Efficient Slag Handling: Slag pots provide a convenient and efficient means of handling molten slag. They are specifically designed to safely contain and transport the hot slag from the furnace or ladle to the designated dumping area. The wide mouth and pouring features of slag pots enable easy and controlled pouring, minimizing spillage and ensuring efficient slag disposal.

2. Enhanced Productivity: Efficient slag handling with the use of slag pots can contribute to improved productivity in the steelmaking process. Slag pots allow for quick and controlled pouring of slag, reducing downtime and optimizing the utilization of furnace or ladle capacities. This helps to maintain a continuous production flow and maximize the efficiency of steelmaking operations.

3. Customization and Cost-effective: Slag pots can be customized to meet specific requirements and operational needs. They can be tailored in terms of size, capacity, lining materials, and additional features to suit different steelmaking processes. This flexibility allows for efficient slag handling and disposal in various production environments.